Published

Last 1 week

Last 30 days

Latest 24 hours

Seniority

Published

Profession

Industry

Seniority

3

jobs

Burn

Kano, Nigeria

Armorsil West Africa Limited

Kano, Nigeria

Alan & Grant

Kano, Nigeria

Malaria Consortium

CLOSEDKano, Nigeria

eHealth Africa

CLOSEDKano, Nigeria

eHealth Africa

CLOSEDKano, Nigeria

Technoserve

CLOSEDKano, Nigeria

Technoserve

CLOSEDKano, Nigeria

Compovine Technologies Limited

CLOSEDKano, Nigeria

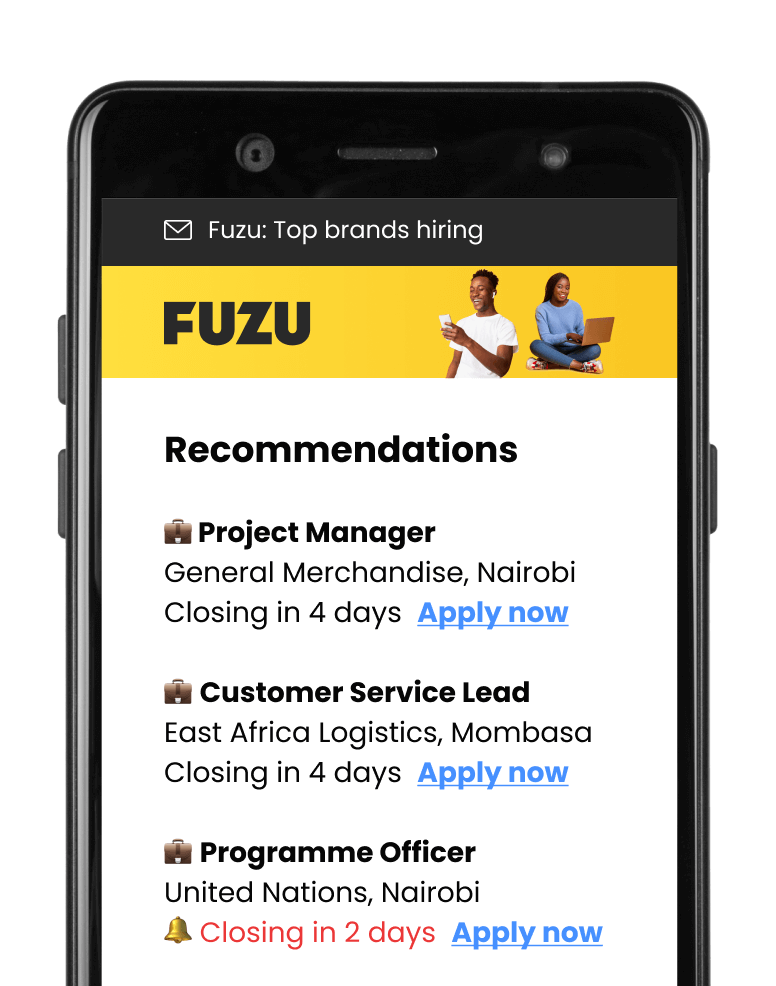

Get personalised job alerts directly to your inbox!

LifeBank

CLOSEDKano, Nigeria

Closing: May 23, 2024

15 days remainingPublished: May 8, 2024 (1 day ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

Desired Character:

Desired Character:

Duties

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.